CONQUERING CLEANING AND SANITATION CHALLENGES OF THE FOOD INDUSTRY

Our powerful, user-friendly line of industrial dry-vapor steam machines will help you easily comply with regulatory codes and laws, all while saving time, saving resources and saving money.

Whatever your food processing sanitation needs are: spot cleaning, CIP/COP/SIP/SOP, or even specifically conveyor belt cleaning and sanitation, the OPTIMA STEAMER is the right choice.

View our validated log reduction tests on common pathogens.

-

OPTIMA STEAMER Food Processing 육가공 식품공장 스팀세척관리

OPTIMA STEAMER Food Processing 육가공 식품공장 스팀세척관리 -

Chopping Board Clean & Sanitization - ASMR | Oddly Satisfying ASMR

Chopping Board Clean & Sanitization - ASMR | Oddly Satisfying ASMR -

OPTIMA STEAMER Video Medley - Various Industrial Applications

OPTIMA STEAMER Video Medley - Various Industrial Applications

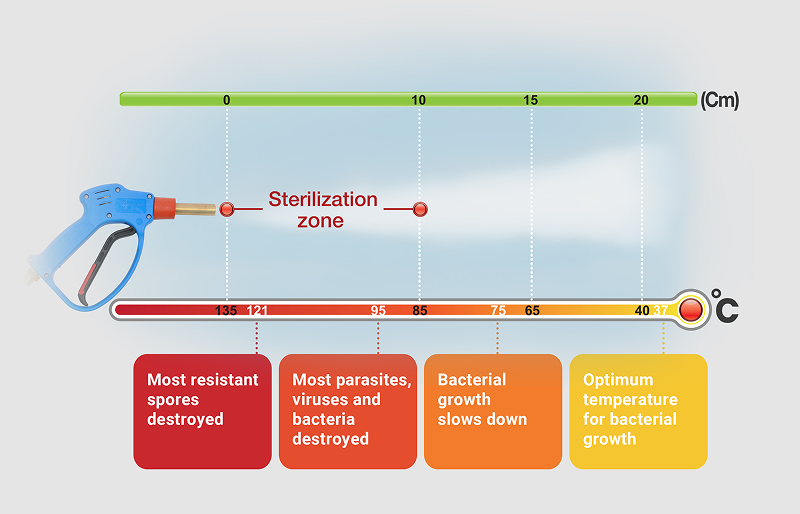

Temperature

DRY STEAM reaches temperatures well above 100°C, water’s boiling point and what makes it a steam.

Hot water and/or wet steam (delivered by hot water pressure washers without a true boiler) only create diffused water particles or mist, and the output is below 100°C.

Surface Penetration

DRY STEAM, being steam, can penetrate surfaces quicker and further—delivering sanitizing temperatures deeper, faster.

Hot water and/or wet steam takes time penetrate into surfaces and the lower temperatures aren’t as effectively transferred.

Waste Water

DRY STEAM is a steam and has far fewer water molecules, producing little to NO waste water—perfect for dry clean facilities.

Hot water and/or wet steam leads to runoff and requires drainage—bad for cleaning and sanitation.

· Quickly reach sanitizing, high temperatures

· Safe, low-pressure output (<125 psi)· Proven efficacy on food pathogens

· Controlled cleaning: CIP, COP, SIP, SOP

· Save time: convert COP to CIP

· Minimize waste water