-

Conveyor Belt Steam Cleaning for Commercial Bakeries

Conveyor Belt Steam Cleaning for Commercial Bakeries -

Steam Cleaner for Conveyor System (Short Introduction)

Steam Cleaner for Conveyor System (Short Introduction)

OPTIMA STEAMER PNEUMATIC CONVEYOR BELT CLEANING TOOL

Pneumatically driven by an air compressor, this oscillating conveyor belt cleaning tool mounts on the belt to clean and sanitize in place.

The moving steam head is fully adjustable to deliver the full power of the the steam jet to entire surface of the belt, maximizing the cleaning and sanitizing power for belts up to 1,220mm wide.

Eliminate the hassles and manpower of disassembling, moving, washing, drying and reassembling conveyor structures out of place.

Save money by reducing water consumption and the use of chemicals.

The OPTIMA Conveyor Belt Cleaning Tool uses a pneumatic-driven system to carefully and precisely deliver the OPTIMA’s powerful, sanitizing superheated steam, eliminating the need for stopping production.

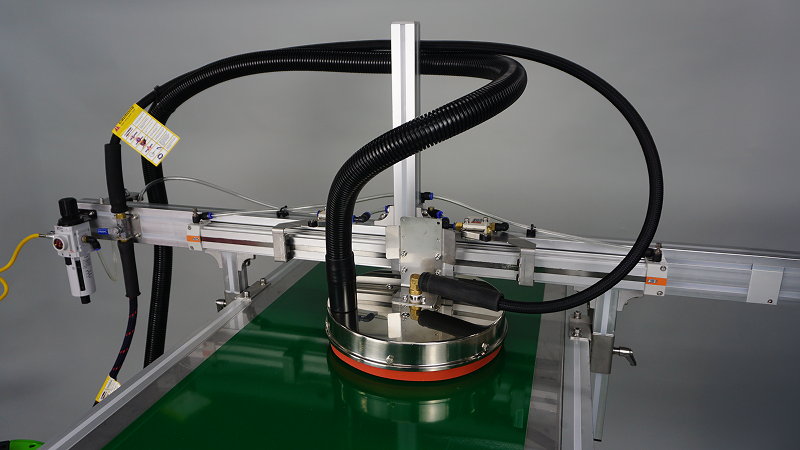

OPTIMA STEAMER PNEUMATIC SPINNER CONVEYOR BELT CLEANING TOOL

Our pneumatically driven pneumatic spinner conveyor belt cleaning tool, powered by an air compressor, is designed for efficient in-place cleaning and sanitizing of conveyor belts.

The oscillating steam spinner head features three high-temperature nozzles that rotate inside a cylindrical housing, delivering powerful steam to cover the entire surface of the belt up to 1,220mm wide.

The tool effectively removes contamination such as chocolate, sugar residues, fats, and sticky substances without the use of harsh chemicals, waste water, or overspray, ensuring a safe and eco-friendly cleaning process with no production downtime.

When needed, the system can be paired with a heat-resistant vacuum hose and a wet vacuum cleaner for simultaneous suction of debris and moisture.

The wide coverage of the 300mm diameter spinner head, combined with adjustable steam delivery, ensures thorough cleaning and sanitization for your conveyor belt.

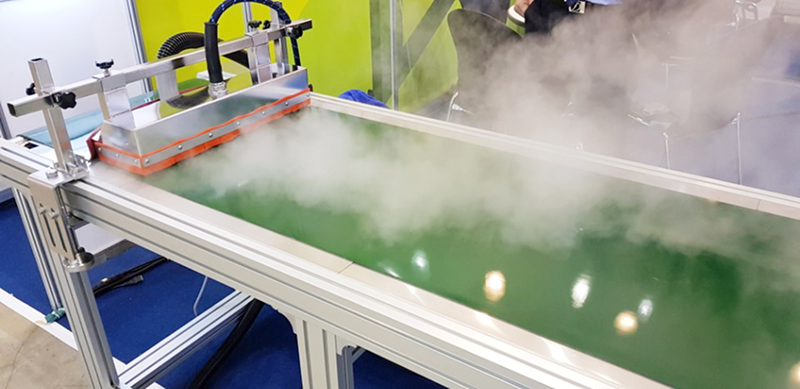

OPTIMA STEAMER VACUUM-SUCTION CONVEYOR BELT CLEANING TOOL

This tool mounts above conveyor belts and uses dry steam from the OPTIMA STEAMER to quickly clean and sanitize as the belts run.

Steam is delivered in an enclosed compartment to aid in sanitation and eliminate overspray contamination, while waste matter is removed via port for vacuum hook-up. Cleaning compartment measures 500mm wide.

Powerfully clean and sanitize flat belts up to 500mm wide while leaving behind a virtually dry surface.

Tackles chocolate, sugar residues, fats and sticky substances with no waste water, no overspray, no harsh chemicals, and no downtime!

The position can be adjusted for larger belts, allowing for complete cleaning in multiple passes.